Brief Introduction:

GOODCRETE CS is a kind of mixed aqueous solution with inorganic silicate as the main ingredient, supplemented by some functional additives. It can effectively penetrate into the concrete for sealing and hardening, constantly increase the hardness and strength of concrete, after treatment to achieve the effect of solid as steel, bright and shiny, can effectively control the concrete floor dust, improve the hardness of the ground and abrasion resistance, the use of simple and economical, so that the treated concrete more resistant to chemical erosion, and can make the polished concrete floor looks more beautiful.

Testing Standards

1、Conforms to JC/T 2158-2021 penetrating liquid hardener.

2、Conforms to GB 18582-2008 Limit of harmful substances in interior wall coatings of interior decoration materials.

Technical index:

Exterior condition: Transparent liquid, odorless

Ph: 11

Intensity: 1.15

Freezing point: -2℃

Boiling: 110℃

24-hour surface water absorption: ≤5mm

Reduction rate of surface water absorption in 24 hours: ≥80

Abrasion resistance ratio:≥ 140%

Poisonous: Not have

Flammable: Non-flammable

VOC: Not have

Reaction Principle:

GOODCRETE CS is a water-based, colorless, transparent and easy-to-use flooring material. It can penetrate into the concrete and concrete calcium, magnesium ions in the chemical reaction to generate a hard polycrystalline silica, fill the pores of the concrete, improve the strength of concrete and wear resistance, but also to play the anti-dusting and sanding, non-slip, anticorrosive, easy to clean, to improve the brightness of the ground, greatly extending the service life of the ground.

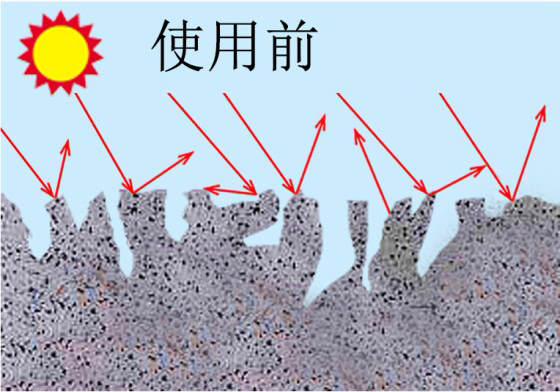

before use

◎Untreated concrete surfaces reflect light poorly

◎Light tends to scatter, resulting in a dull look

◎Untreated concrete surfaces look like decayed teeth, they are fragile and wear on the surface can lead to breakage and poor abrasion resistance.

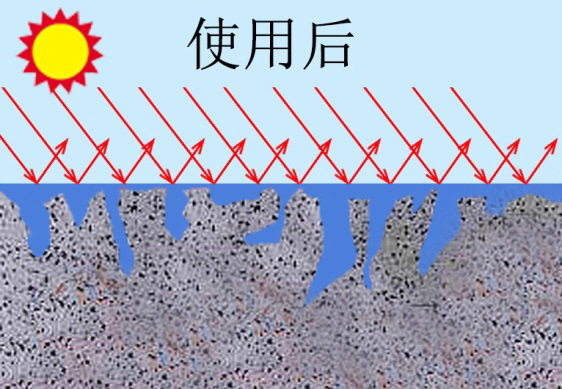

After use

◎The treated concrete surface reflects light more evenly.

◎Fills in the voids in the concrete and blends in with the concrete.

◎With regular maintenance and daily rubbing, the surface will have a long-lasting luster.

Characteristics:

Hard: The treated concrete floor will reach 7 degrees on the Mohs hardness scale.

Abrasion Resistance: Cures the various components in the concrete into a hard solid, increasing abrasion resistance.

Friction: Improvement of 22.5% for dry surface and 47.6% for wet surface.

Dustproof: Chemical reaction with silicate in concrete, forming a dense whole, controlling the precipitation of dust from the pores.

Anti-slip: It prevents saline and alkaline components from precipitating out of the surface, thus preventing slippery and alkaline phenomenon on the concrete surface.

Anti-seepage: It can effectively penetrate into the concrete and lock the pores, inhibiting water, oil and other dirt from entering the concrete.

Anti-aging: Effectively prevents chlorine ions and ultraviolet radiation, concrete will not be affected by exposure to electromagnetic or water spray.

Corrosion resistance: After one month of treatment, the corrosion resistance of the concrete floor is greatly improved.

Bonding power: the bonding power with epoxy resin is increased by 21.9%, and the bonding power with coating is basically unchanged.

Curing power: In the process of maturing concrete for one day, the water retention rate is increased by 94.5%, preventing cracking.

Brightness: The treated concrete floor will appear marble-like luster, the longer it is used, the better the luster.

Environmentally friendly: colorless, odorless, non-flammable, non-toxic and free of VOC substances.

Long-lasting: continuous crystallization and densification, the more you use it, the harder it gets and the brighter it gets.

Advantages:

◎No film, penetrate into the concrete 5-8mm, sealing the concrete surface.

◎It integrates with concrete, does not crust, and will never fall off.

◎Excellent hardening, densification and dustproof effect.

◎The longer it is used, the harder and denser it becomes, and the more attractive luster it shows.

◎After full reaction, it can effectively resist acid and alkali erosion when cleaning.

◎Water-based product, non-combustible. It meets the requirement of fire prevention.

◎Non-toxic, can be used in food processing places.

◎No special maintenance, washing and mopping can be done.

Method of Using:

1. Preparation:

A :Brooms, mops, buckets, vacuum cleaners, sprayers, brushes, grinders, high-polishers, abrasive pads, abrasive pads, masks, gloves, and overalls.

B :The concrete surface is required to be clean, make sure the concrete surface is dry or slightly damp and free from any debris and pollutants. Construction temperature: 5-40℃.

2. Spraying dosage:

The dosage of standard C30 concrete is around 3-5 square meters per kilogram.

The dosage of emery is about 8-10 square meters per kilogram.

3. Construction method:

For new concrete floor, generally at least 3 to 7 days of maintenance after the use of Goodcrete CS sealer effect is better. In the old ground, before using the ground loose layer using a grinder to grind off, repair broken cracks and holes, clean and use the product.

No throw construction: saturated spray, use soft brush to push and roll the material back and forth, after the surface becomes sticky, sprinkle water and continue to push and roll to ensure that the surface is wet for 1 hour.

Grinding and polishing construction:

(1) Use 50 mesh diamond grinding wheel grinding ground leveling, ground leveling this step can be omitted.

(2) Use 50 mesh, 150 mesh, 300 mesh resin grinding wheel grinding ground, grinding surface clean off the mud.

(3) Saturated spray material, with a soft brush to push back and forth, the surface becomes sticky after sprinkling water to continue to push the roll, to ensure that the surface is wet for 1 hour.

4)After drying, use 500 mesh, 1000 mesh resin sheet to grind the ground, clean off the surface mud after grinding.

5)After the ground is dry, use 1500 mesh, 2000 mesh, 3000 mesh polishing.

Ground treated with Goodcrete CS is strong and dense, increasing in density and hardness during the subsequent crystallization process.

9. First aid measures:

EYE CONTACT: Rinse with water for 15 minutes or more; if eye irritation does not resolve, seek medical attention.

Skin contact: Wash with water and soap.

Ingestion: Do not induce vomiting, drink plenty of drinking water to dilute, and seek medical attention.

Packing:

5gallon/pail, 55gallon/barrel, or 20kg/pail, 220kg/barrel.

Storage Life:

Store in a cool, dry environment.Product must be kept away from children to avoid child contact.

Shelf life is 10 years in the original sealed condition.

|